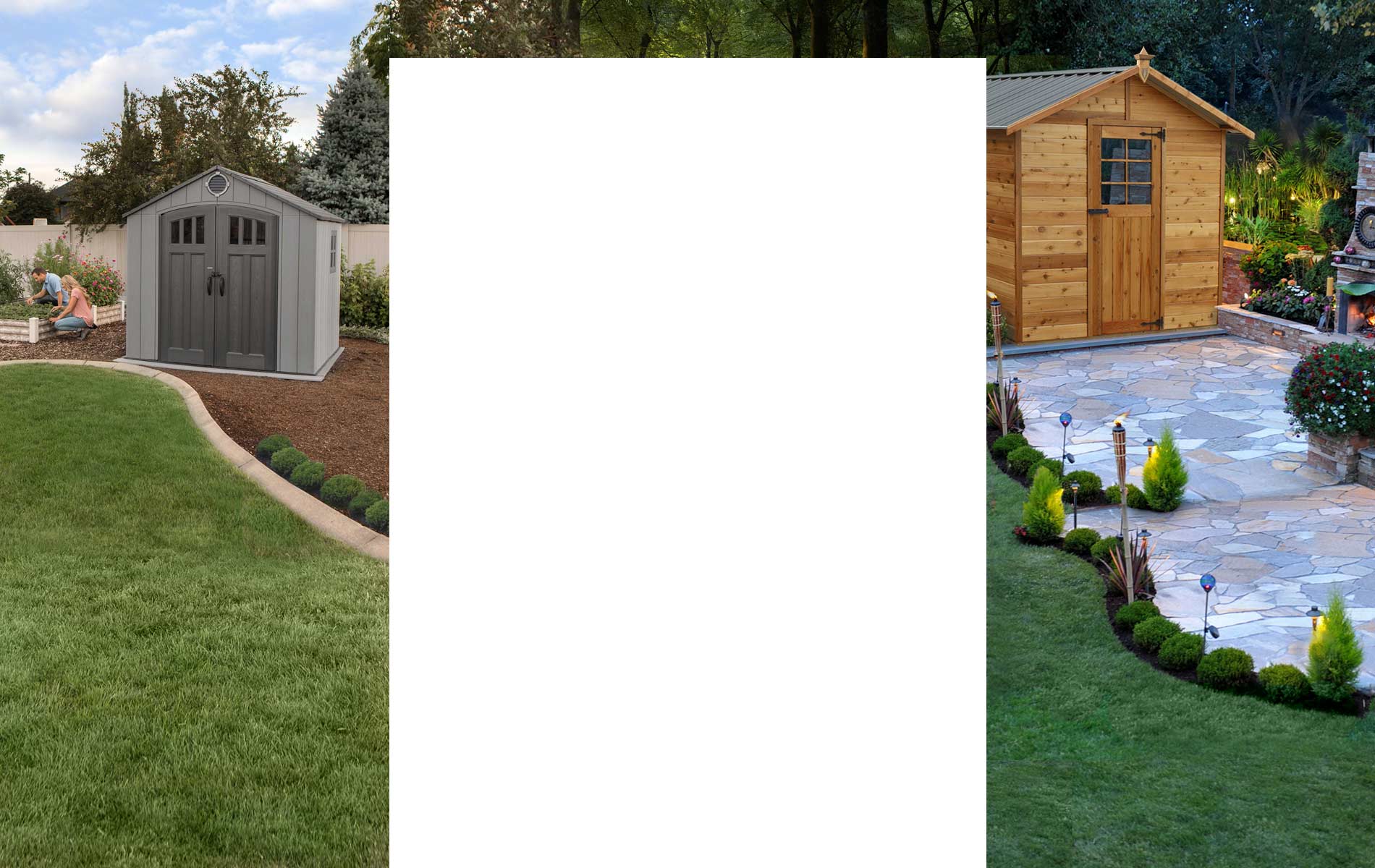

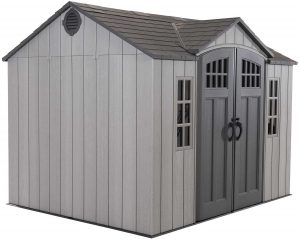

Plastic garden sheds are becoming more popular and widely used in Australia

Nearly every residence in Australia, from farming properties right through to apartments and units, has a need for some form of outdoor storage, such as garden sheds or cabinets. Some items like lawn mowers and garden implements are simply not the sort of thing we want inside; others such as cans of fuel have to be stored away from the house to meet the requirements of insurance policies.

This type of storage is often a garden shed, although other options including outdoor storage benches and cabinets are becoming more widely used.

Traditionally, the backyard shed was framed up with whatever timber was available and clad with corrugated iron sheet. During the 1970’s new ranges of garden sheds became available through garden centres and hardware stores. Some of these are supplied as pre-assembled panels made from galvanised, Zincalume or Colorbond steel sheet, and some as kit form cartonised units made from coated steel or aluminium. Aluminium is not used today for garden sheds, as it is relatively expensive and not as strong in sheet form.

During the past 10 years or so, plastic garden sheds have been gaining acceptance as an alternative to the metal units. Mostly these are manufactured from polypropylene resin which gives a good balance between strength, weathering (including UV resistance) and cost. Some manufacturers have just started using polycarbonate for garden sheds – the high impact resistance of this product makes them virtually indestructible.

As with most questions, there are pros and cons for both types of shed – some of these are as follows:

METAL GARDEN SHEDS

PROS

- Price – steel sheds are available at lower costs than plastic sheds; typically about half the cost per square metre of floor area, (most steel shed manufacturers are in a race to the bottom on price making most products very low quality)

- Wide range of sizes and colours – units from 1.5m x 0.78m up to 6.0m x 3.0m are available in Zincalume and in many of the standard Colorbond colours

- Readily available – many sizes can be purchased from stock at hardware stores

CONS

- Difficult to assemble, many sheds of this type have misaligned holes or require all holes to be drill by the installer.

- Quality – there is a wide variation in the quality of units available; a good rule of thumb is the old saying: “You get what you pay for”

- Base preparation – generally the metal garden shed kit does not include a floor; this necessitates base preparation which could include either constructing a timber floor or laying a concrete slab for the unit

- Susceptibility to damage – steel sheds are relatively easy to scratch and dent, particularly the cheaper units which are made from very light gauge sheet and problems are often encountered with sliding doors jamming because of light construction

PLASTIC GARDEN SHEDS

PROS

- Long-lasting – the plastic used for garden sheds has good impact resistance and UV stability, allowing the units to retain a good appearance for extended periods and offering long product life

- Includes floor – the floor section is an integral part of the shed structure, providing a weatherproof storage space and obviating the need for a separate base or extensive base preparation

- Good looking – the molded section construction allows for a different and attractive appearance

- Ease of assembly – comprehensive instructions and good product design make the assembly process straightforward

CONS

- Cost – poly resin sheds are more expensive than steel units; typically more than twice as much for a similar floor area

- Limited range of sizes– only sizes of up to 14 square metres floor area are available currently

Conclusion? It depends on your priority – if cost is the deciding factor a steel shed is the answer and if appearance and product life is more important to you – a poly resin or polycarbonate plastic unit is the logical choice.

Comments are closed.